Shrimp Grading Machine

Category:

Food Processing Equipment

WhatsApp:

Email:

- Details

-

- Commodity name: Shrimp Grading Machine

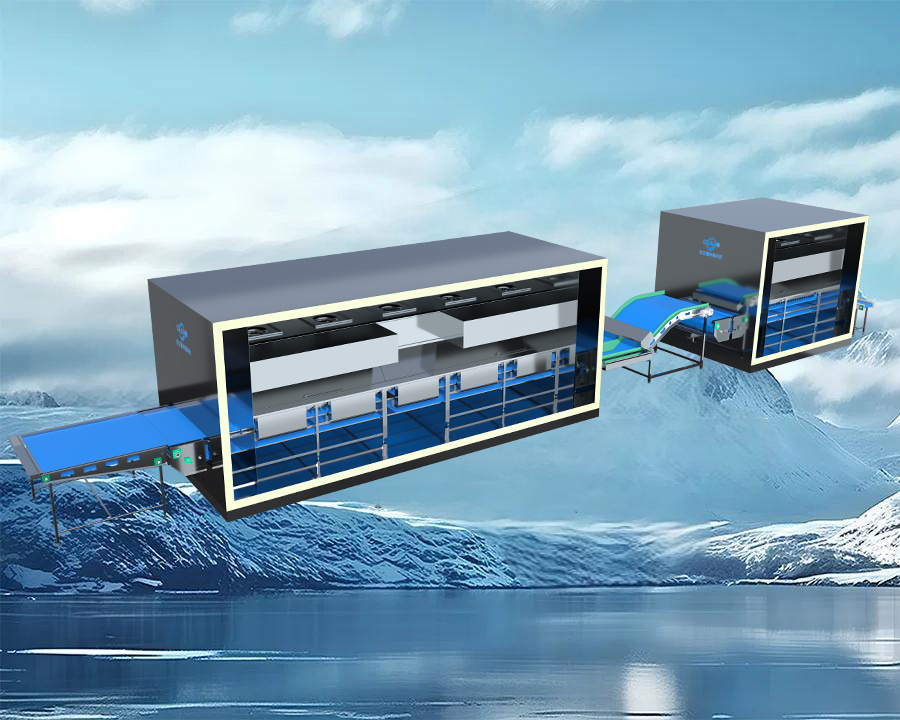

Shrimp Grading Machine is designed for grading shrimps of different sizes.The grader offers a gentle and accurate grading for both cold water shrimp and anwarm water shrimp.After the feed system releases and orients raw shrimps,grading(sorting)occurs as raw shrimps fall into grading lanes that is the gap between rollers and move down diverging,continuously rotating rollers.Raw shrimps are sorted by size,starting with the smallest size and ending with largest size.

Product Description

Grand shrimp grader adopts plastic steel belt which is anti-oil and anti-erode, also is easy to clean. This machine can grade shrimp into 5 classes, the size of each class can be adjustable; the complete machine is made of SUS304 except belt, motor and electricity elements. The machine is designed to operate easily and intuitively, the control is lumped and digital.

Constitute:

This shrimp sorting machine is composed by soak elevator, second elevator and rotary grader and other matched spraying pipes,outlet conveyor and controller, etc.

Features:

Put the raw materials into the first grading tank to convey and process automatically;

Work is fast , accurate and uniform to classify;

There is no breakage to the products;

Save energy cost and has high working efficiency;

The material conveyor and material recovering conveyor are all made of food grade plastic,have no pollution to the food and meet food sanitation requirements.

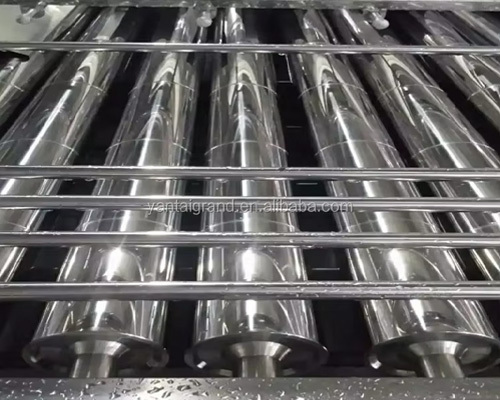

The space between screen rollers can be adjusted by hand, or self-regulate, and it is very flexible and convenient to adjust.

Products Show

Main Usage:

Grand prawn grading machine is suitable for shrimp, headless shrimp, shrimp meat and cooked shrimp, and other similar products.

Main Character :

Put the raw materials into the first grading tank to convey and process automatically;

work is fast , accurate and uniform to classify;

There is no breakage to the products;

Save energy cost and has high working efficiency;

The material conveyor and material recovering conveyor are all made of food grade plastic,have no pollution to the food and meet

food sanitation requirements.The space between screen rollers can be adjusted by hand, or self-regulate, and it is very flexible and convenient to adjust.

Technical Parameters

Dimensions

6980*4800*2380

Roller

(∅ 125 × 130mm) 18 stainless steel rollers

Conveyor belt size

1746mm wide plastic mesh belt, 10mm height of the baffle, two-stage hoist

Conveyor belt material

high-strength PVC plastic steel belt

Power

(1.5KW × 1 set), (0.4KW × 2 sets), (0.755KW × 2 sets), (stainless steel pure water pump 1.1KW × 1 set), (MITSUBISHI inverter)

Lifting groove material

sus1.5mm 304# stainless steel plate

Body material

(∅114×2.5mm) stainless steel tube

Water supply part

stainless steel fittings on the cover, stainless steel pump PPR fittings

Rotating part

UCF205 stainless steel bearing, shaft drive (bearings are all stainless steel)

Power distribution cabinet

microcomputer control, stainless steel electric cabinet

Production

2 ton - 2.5 tons per hour

Packing&Shipping

Real Case Scenario

Shrimp Peeling Machine

Related downloads

Recommended Products

Online Message

SAF Coolest v1.2 设置面板 ZDUSX-ZQZG-DSAQE-DAD

无数据提示

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页