Tunnel Freezer

Category:

Refrigeration Equipment

WhatsApp:

Email:

- Details

-

- Commodity name: Tunnel Freezer

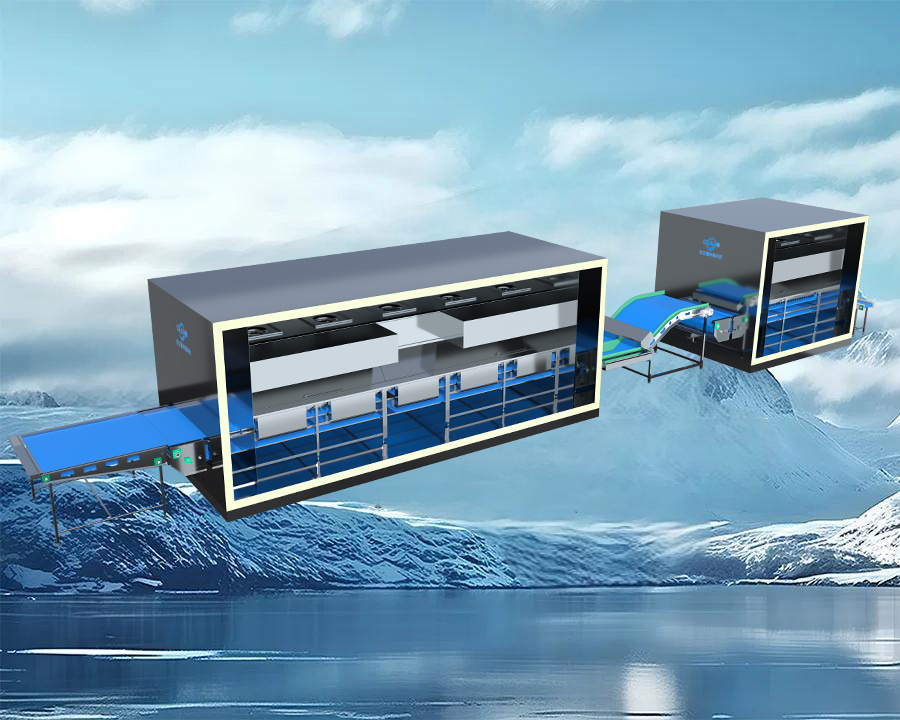

IQF tunnel freezer is a simple structure, highly efficient freezing equipment. There are stainless steel solid belt tunnel freezer and mesh belt tunnel freezer. It is effective in freezing seafood, poultry, vegetable, fruits, pastry, diary products, etc. Freezing capacity is between 500kg-2000kg/h.

Product Description

Tunnel freezer is a quick freezing machine with simple structure and reliable operation. It is widely used for IQF freezing of aquatic products, pastry, meat products, dairy products, prepared foods and etc. It can be customized on design and manufacturing according to customers' demands and room limitation.

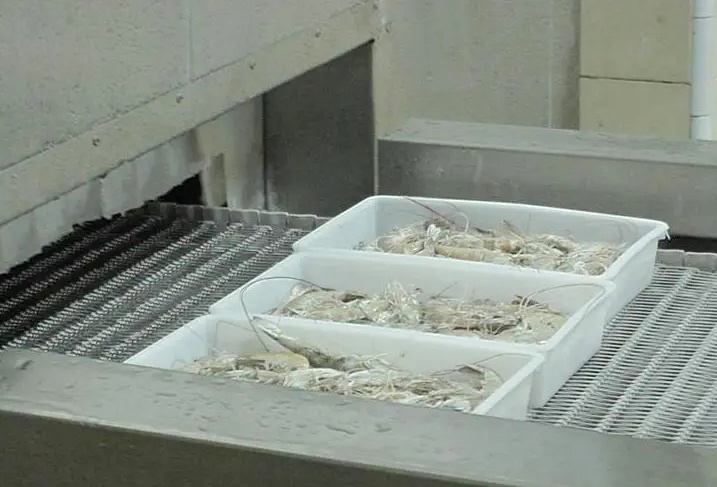

The function of a tunnel type freezer is to quickly freeze seafood such as scallops, clam meat, oyster meat, etc; Fish and shrimp:Larimichthys polyactis, shrimp, lobster tail, etc; Pasta category: dumplings, steamed buns, etc; Vegetables; Fruits and other products quickly cool down to a frozen state. To achieve the goal of not losing nutrients, preventing product deterioration, air drying, and maintaining the same appearance.

Tunnel type quick freezing machine is mainly composed of refrigeration system,propulsion system, electrical control system and quick freezing room. The staff will send the plates containing fish and shrimp,dumplings, rice dumpling and Wonton to be frozen through the quick freezing entrance into the track of the quick freezing machine and move towards the exit. In the process of moving, a stable vertical annular low temperature airflow will be formed under the action of a fan, This low-temperature airflow exchanges heat with horizontally moving frozen food, thereby achieving a rapid cooling and freezing process.

Real Case Scenario

Structural features:

1. High production capacity in a smaller footprint than conventional spiral freezers.

2. Low operating cost through maximized cryogen efficiency.

3. Higher frozen product quality from a quicker freeze.

4. Reduced labor for cleaning and improved food safety through hygienic design.

5. Less product dehydration through reduced freezing time resulting in higher product yieldTechnical Parameters

Mode Capacity Size Voltage Material GSD-500 500kg/h 13500*3000*2500mm Customizable SUS304 GSD-1000 1000kg/h 21500*3000*2500mm Customizable SUS304 GSD-2000 2000kg/h 29200*4100*2500mm Customizable SUS304 Products Show

The entire machine is mainly made of 304 stainless steel, and the warehouse body is assembled with 120mm thick double-sided stainless steel hard polyurethane sandwich panels to prevent cold running Copper tube aluminum fins with three variable pitch designs can be used for a long time at low temperatures with minimal frost formation, effectively extending production time

The mesh belt is made of high-quality and highly elastic stainless steel wire, which is resistant to low temperatures, has a flat surface, and strong load-bearing capacity. Real Case Scenario

Contact Plate Freezer

Related downloads

Recommended Products

Online Message

SAF Coolest v1.2 设置面板 ZDUSX-ZQZG-DSAQE-DAD

无数据提示

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页